|

NAPHTHA

Please use our

A-Z INDEX

to navigate this site

So

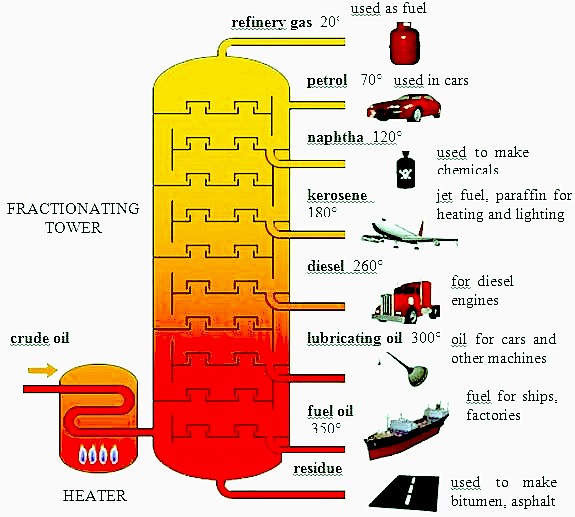

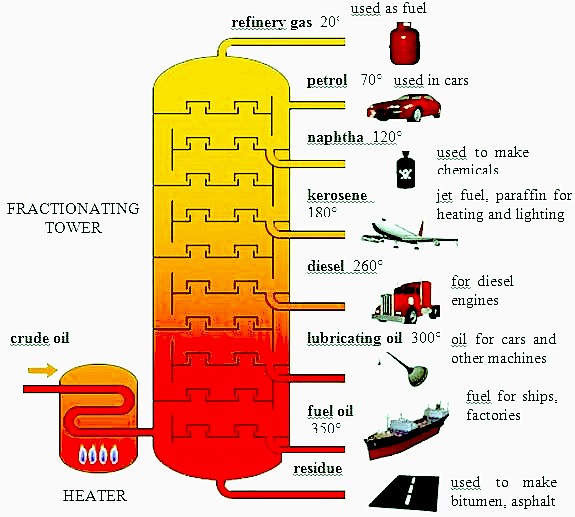

how do we make plastic? It all begins with fractional

distillation of crude oil and the cracking of of distillates

with catalysts to make polyolefins.

FRACTIONAL

DISTILLATION

Petroleum naphtha is an intermediate hydrocarbon liquid stream derived from the refining of crude oil.

There are hundreds of different petroleum crude oil sources worldwide and each crude oil has its own unique composition or assay. There are also hundreds of petroleum refineries worldwide and each of them is designed to process either a specific crude oil or specific types of crude oils. Naphtha is a general term as each refinery produces its own naphthas with their own unique initial and final boiling points and other physical and compositional characteristics.

Some refinery naphthas also contain some olefinic hydrocarbons, such as naphthas derived from the fluid catalytic cracking, visbreakers and coking processes used in many refineries. Those olefin-containing naphthas are often referred to as cracked naphthas.

Some petroleum refineries also produce small amounts of specialty naphthas for use as solvents, cleaning fluids, paint and varnish diluents, asphalt diluents,

rubber industry solvents, dry cleaning, cigarette lighters, recycling products, and portable camping stove and lantern fuels. Those specialty naphthas are subjected to various purification processes.

Sometimes the specialty naphthas are called petroleum ether, petroleum spirits, mineral spirits, paraffin, benzine, hexane, ligroin, white oil or white gas, painters naphtha, refined solvent naphtha and Varnish makers' & painters' naphtha (VM&P). The best way to determine the boiling range and other compositional characteristics of any of the specialty naphthas is to read the Safety Data Sheet (SDS) for the specific naphtha of interest.

On a much larger scale, petroleum naphtha is also used in the petrochemicals industry as feedstock to steam reformers and steam crackers for the production of

hydrogen (which may be and is converted into ammonia for fertilizers), ethylene, and other olefins. Natural gas is also used as feedstock to steam reformers and steam crackers.

Modern steam cracking plants are very large, usually producing 1-2 million tonnes of products annually and several have been built recently that can have an output of nearly 3 million tonnes a year and cost about 1

billion dollars to

build, where we should perhaps be scaling down in a

sustainable society.

The reactant gases (ethane, propane or butane) or the liquids (naphtha or gas-oil) are preheated and vaporised, are mixed with steam and heated to 1050-1150 K in a tubular reactor (Figure 3). They are converted to low relative molecular mass alkenes (plus by-products).

Polymerization

When many molecules of a simple compound join together, the product is called a polymer and the process is termed polymerization. The simple compounds are generally produced in the refinery and the polymers, such as poly(ethene) and poly(propene) are often manufactured nearby.

Small polymers, known as oligomers, are also produced from the refinery products. One important example is the production of alkenes with 10-14 carbon atoms from ethene, used in the manufacture of alkyl sulfonates, an important

surfactant.

REFINING - 42 gallons per barrel makes about 19½ gallons of gasoline, 9 gallons of fuel oil, 4 gallons of jet fuel, and 11 gallons of other products, including lubricants, kerosene, asphalt, and petrochemical feedstocks to make plastics. That adds up to more than 42 gallons because of something called "refinery gain" - the processing and chemical changes increase the volume.

Plastic

has become essential to modern living. There

is nothing wrong with plastic if it is disposed of carefully

and recycled. This

gives us very good reason to try and develop a system for making

the best use of plastic, and this includes recycling it way

more effectively than before, with an ocean safety net.

We

have just one ocean and one planet: Planet

A and Ocean

A. There is no Planet

B with an Ocean

B.

|

CHEMICAL

COMPANY

A - Z

|

EMPLOYEES

|

$

BILLIONS

|

|

-

|

-

|

- |

|

ALPLA:

|

17,300

|

3.3 |

|

Аrkema

SA:

|

20,000

|

8.8 |

|

BASF:*

|

39,000

|

63.7 |

|

Berry

Global:*

|

-

|

- |

|

Borealis

AG:

|

-

|

- |

|

Borouge (Abu Dhabi Polymers Co Ltd):

|

6,500

|

7.2 |

|

Braskem

SA:*

|

-

|

- |

|

ChevronPhillips

Chemical:

|

5,000

|

13.4 |

|

Clariant:*

|

-

|

- |

|

CNPC:(

China National Petroleum Corp):

|

1,470,190

|

326.0

|

|

Covestro:*

|

-

|

-

|

|

CP

Group:*

|

-

|

-

|

|

Dow Chemicals:*

|

14,000

|

49.0 |

|

DSM:

|

-

|

- |

|

DuPont:

|

-

|

- |

|

ENI

S.p.A.

Ente Nazionale Idrocarburi (Versalis):*

|

33,000

|

61.6 |

|

Exxon

Mobil:*

|

75,600

|

290.0 |

|

Formosa Plastics Corporation:*

|

2,800

|

5.0 |

|

Henkel:*

|

-

|

- |

|

INEOS

(Ineos Group AG):

|

19,000

|

60.0 |

|

Lanxess:

|

16,700

|

7.9 |

|

LG

Chem:

|

14,000

|

17.8 |

|

Lyondell

Bassell:*

|

13,000

|

33.0 |

|

Mitsubishi Chemical

Holdings:*

|

-

|

- |

|

Mitsui

Chemicals:*

|

-

|

- |

|

NOVA

Chemicals:*

|

-

|

- |

|

OxyChem:*

|

-

|

- |

|

Polyone

Corp:*

|

-

|

- |

|

Procter &

Gamble:*

|

-

|

- |

|

Reliance

Industries Ltd:*

|

-

|

- |

|

Repsol

SA:

|

-

|

- |

|

Sasol

Ltd:*

|

-

|

- |

|

SABIC:

(Saudi Arabia Basic Industries Corp)*

|

40,000

|

35.4 |

|

SCG

Chemicals:*

|

-

|

- |

|

Shell:*

|

-

|

- |

|

Sinopec:

|

249,000

|

314.4 |

|

Suez:*

|

-

|

- |

|

Sumitomo

Chemical:*

|

-

|

- |

|

Tosoh

Corp:

|

-

|

- |

|

Total

SA:*

|

-

|

- |

|

Veolia:*

|

-

|

- |

* Denotes membership of the AEPW

LINKS

& REFERENCE

http://www.petroleum.co.uk/refining

ABS

- BIOMAGNIFICATION

- CANCER

- CARRIER

BAGS - COTTON

BUDS - DDT

- FISHING

NETS - HEAVY

METALS - MARINE

LITTER

MICROBEADS

- MICRO

PLASTICS - NYLON

- PACKAGING

- PCBS

- PET

- PETROLEUM

- PLASTICS

- POLYCARBONATE

- POLYOLEFINS

POLYPROPYLENE

-

POLYSTYRENE

- POLYTHENE - POPS

-

PVC - SHOES

- SINGLE

USE - SOUP

- STRAWS

- WATER

Please use our

A-Z INDEX

to navigate this site

This website is

provided on a free basis as a public information service. copyright © Cleaner

Oceans Foundation Ltd (COFL) (Company

No: 4674774) 2019. Solar

Studios, BN271RF, United Kingdom.

COFL is

a company without share capital.

|