|

RECYCLING TECHNOLOGIES LTD

PLEASE USE OUR A-Z INDEX TO NAVIGATE THIS SITE

|

|

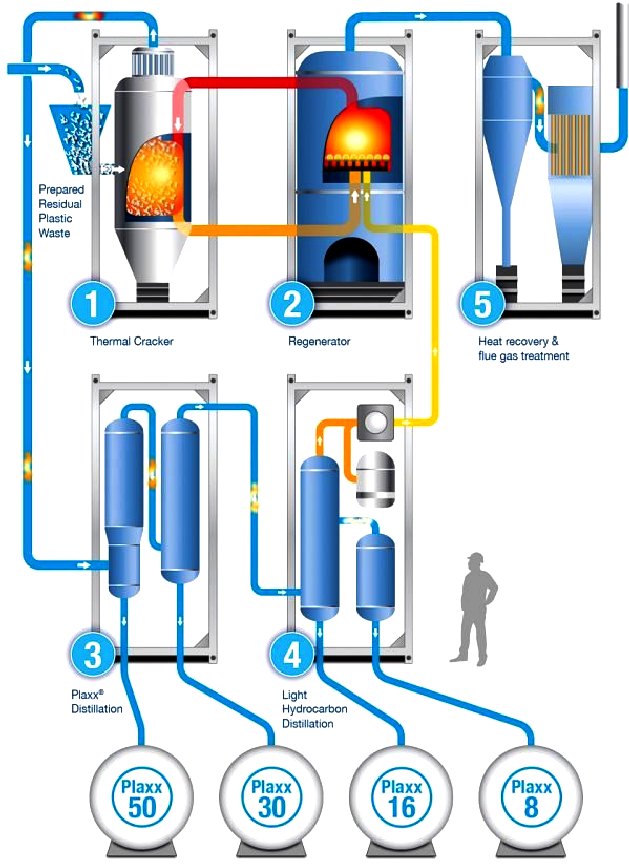

Recycling Technologies (RT) has engineered a modular and scalable machine named the RT7000, to chemically convert plastic waste, which currently cannot be recycled, into Plaxx® - a valuable hydrocarbon product.

The machine is sized to be installed at existing waste sites and recycling centres, diverting residual plastic waste from ending up

in landfill sites, incinerated or exported overseas.

CIRCULAR

ECONOMY

The majority of currently “un-recyclable” plastic waste is currently destined for incineration, export, or landfill. By diverting this waste to the RT7000 and returning it to its original

oil state, plastic waste is valorised as a resource allowing

RT to:

The RT7000 makes the use of plastic sustainable, delivering significant environmental benefits both through the correct

management of waste and the production of a sustainable product.

The developments of RT are pushing forward the boundaries of existing processes and business models to refine it such that it becomes a valuable component of the transition to a circular economy. In our view their work is ground breaking and as such this kind of research and development should be supported for potential use in mass conversion such as the landing of ocean plastics.

PRODUCTS

Plaxx is a ultra low sulphur oil, cut into four fractions. These have applications in multiple industrial sectors and can be sold individually or combined dependent on the drives of the local market place.

- Plaxx-30 as Low Sulphur Heavy Fuel Oil (LS HFO) for use in engines/burners

-

The blend of Plaxx-8, Plaxx-16, Plaxx-30 and Plaxx-50 as LS HFO for use in engines/burners with modified fuel delivery systems

-

Plaxx-50 as a petroleum wax in packaging, cosmetics and other applications

Recycling Technologies Limited Unit B2 Stirling Court

PRESS RELEASE

JULY 8 2019 - Unique bins being trialled at Barclaycard presents British Summertime Festival in Hyde Park to help revellers recycle troublesome plastics like bags, crisp wrappers and bottle lids they bring on site.

A BIT ABOUT PYROLYSIS

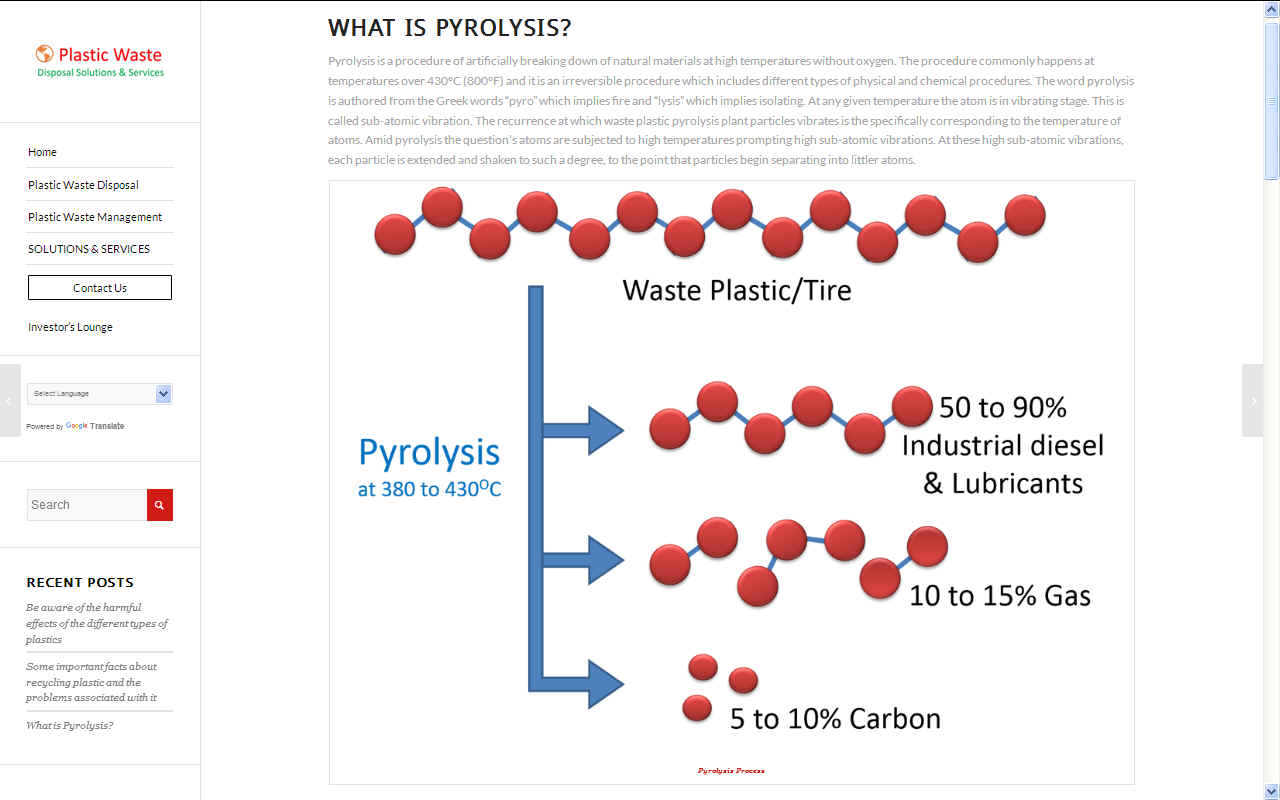

Pyrolysis transforms organic materials into their gaseous components, a solid residue of carbon and ash, and a liquid called pyrolytic oil (or bio-oil).

Pyrolysis has two primary methods for removing contaminants from a substance: destruction and removal. In destruction, the organic contaminants are broken down into compounds with lower molecular weight, whereas in the removal process, they are not destroyed but are separated from the contaminated material.

Pyrolysis is a useful process for treating organic materials that “crack” or decompose under the presence of heat; examples include polychlorinated biphenyls (PCBs), dioxins, and polycyclic aromatic hydrocarbons (PAHs).

Although pyrolysis is not useful for removing or destroying inorganic materials such as metals, it can be used in techniques that render those materials inert.

Aspirational applications of pyrolysis would convert biomass into syngas and biochar, waste plastics back into usable oil, or waste into safely disposable substances.

On the off chance that the cooling of the cooling tube is adequate, there will be no fuel in the bubbler, however in the event that not, the water will catch all the rest of the fuel that will skim over the water and can be poured off the water.

On the base of the cooling tube is a steel store that gathers all the fluid and it has a discharge valve on the base with the goal that the fluid fuel can be spilled out.

SCIENCE DIRECT ABSTRACT - The global plastic production increased over years due to the vast applications of plastics in many sectors. The continuous demand of plastics caused the plastic wastes accumulation in the landfill consumed a lot of spaces that contributed to the environmental problem. The rising in plastics demand led to the depletion of petroleum as part of non-renewable fossil fuel since plastics were the petroleum-based material. Some alternatives that have been developed to manage plastic wastes were recycling and energy recovery method. However, there were some drawbacks of the recycling method as it required high labor cost for the separation process and caused water contamination that reduced the process sustainability. Due to these drawbacks, the researchers have diverted their attentions to the energy recovery method to compensate the high energy demand.

Through extensive research and technology development, the plastic waste conversion to energy was developed. As petroleum was the main source of plastic manufacturing, the recovery of plastic to liquid oil through pyrolysis process had a great potential since the oil produced had high calorific value comparable with the commercial fuel. This paper reviewed the pyrolysis process for each type of plastics and the main process parameters that influenced the final end product such as oil, gaseous and char. The key parameters that were reviewed in this paper included temperatures, type of reactors, residence time, pressure, catalysts, type of fluidizing gas and its flow rate. In addition, several viewpoints to optimize the liquid oil production for each plastic were also discussed in this paper.

OCEAN CLEANUP PROJECTS A - Z

* Adidas * Algalita research foundation * Aliance to end Plastic Waste AEPW * Baltimore Mr Trash river cleaning barge * BAN - Basel Convention Action Network * Boyan Slat's ocean booms * CLAIM H2020 EU marine plastic project * Earth Day - Fact sheet ocean plastic * Fionn Ferreira's ferrofluid extraction of microplastics * FlashLight Press Michelle Lord & Julia Blatt * GRIPS - Global Research & Innovation in Plastics Sustainability * Interceptor tethered river cleaning barges * Junk Raft - plastic awareness voyage * Kids Against Plastic Tat KAPTAT * Miss Ocean - Plastic Awareness Events * 4Ocean recycled plastic bracelets * Nike - Sneakers from recycled materials, ocean spills * Plastic Oceans Org * Seabin * SeaVax autonomous drones * Surrey University PIRATE & Triton * Sussex Bay - Coastline marine rewilding project * WRAP - Waste & Resources Action Programme

LINKS & REFERENCE

https://www.sciencedirect.com/science/article/pii/S0196890416300619 http://www.plasticwastedisposal.com/what-is-pyrolysis/ https://www.epa.gov/energy/greenhouse-gas-equivalencies-calculator https://recyclingtechnologies.co.uk/

|

|

|

ABS - BIOMAGNIFICATION - CANCER - CARRIER BAGS - COTTON BUDS - DDT - FISHING NETS HEAVY METALS - MARINE LITTER - MICROBEADS - MICRO PLASTICS - NYLON - OCEAN GYRES - OCEAN WASTE PACKAGING - PCBS - PET - PLASTIC - PLASTICS - POLYCARBONATE - POLYSTYRENE - POLYPROPYLENE - POLYTHENE - POPS PVC - SHOES - SINGLE USE - SOUP - STRAWS - WATER

PLEASE USE OUR A-Z INDEX TO NAVIGATE THIS SITE

|

|

|

This website is provided on a free basis as a public information service. copyright © Cleaner Oceans Foundation Ltd (COFL) (Company No: 4674774) 2021. Solar Studios, BN271RF, United Kingdom. COFL is a company without share capital.

|